pixel

pixel

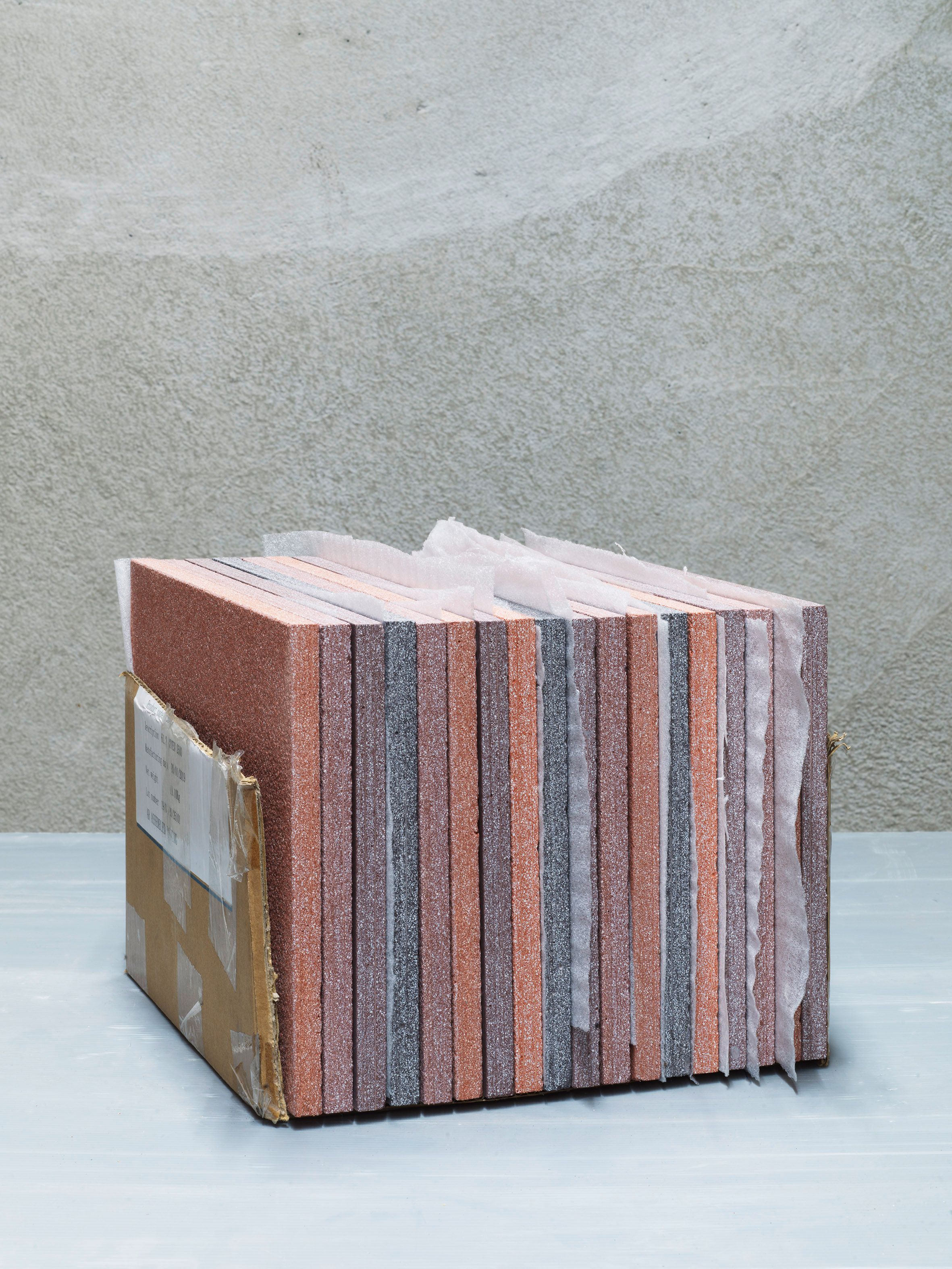

Vivid shingles made of glassfibre reinforced concrete

A new product was developed to reduce waste in production: pixel. They are small-format concrete shingles produced from the residual material generated, for example, by cutting large-size panels. A software will take account of the amount of waste (scrapcrete) and generate project-specific design options for facades. It is not just about recycling residual materials, it is also about creating aesthetically appealing designs.

Transformation from waste to design

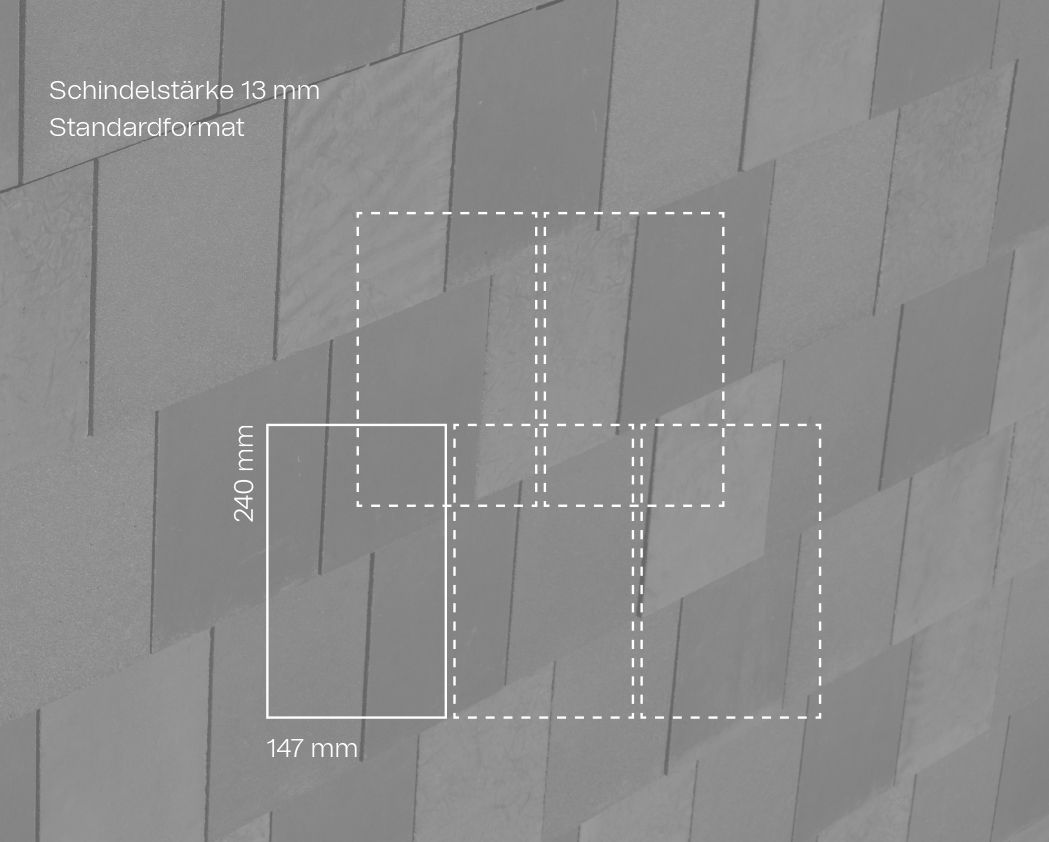

A waste analysis was used over the period of more than one year to determine what percentage of the material was suitable for reuse. Over 106,000 parts were read in, areas, boundaries, shapes, colors and textures were decoded and then classed by size and shape. The potential shapes were used to develop the pixel product, a small-format concrete shingle measuring 147 x 240 millimetres. The format was determined according to the rules of the golden section, in order to give the division ratio of the two sizes a harmonious appearance.

Characteristics

The elements made of glassfibre reinforced concrete withstand extreme loads. Due to their robust properties, the panels are weather-resistant and have a long service life.

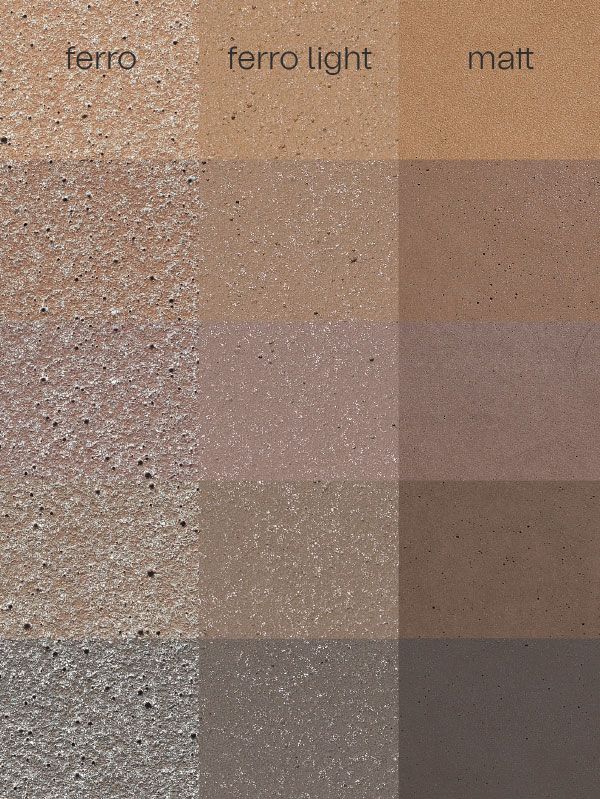

Depending on how the concrete surface is treated, the material is given an individual character both visually and to the touch. Colors on matt surfaces appear more saturated, while blasting makes them less intense.

Products made of fibreC guarantees absolute fire resistance: fire rating A1 - “non-combustible“ approx. according to BBA Agrément Certificate 16/5362 for Great Britain and A2-s1,d0 - “non-combustible“ approx. according to abZ Nr. Z-31.4.166 for Germany.

With its ISO 9001 and ISO 14001 certifications, Rieder sets itself high standards for environmental protection. The environmental product declaration, EPD, gives precise indicators for the life cycle assessment.

Design

Due to their small size, the elements open up entirely new design options for innovative building envelopes. This means that materials made of mineral raw materials not only offer recycling options, but also upcycling options in the form of small shingles. By combining different colors and surfaces of a color collection, pixels give the facade a vibrant yet homogeneous appearance. Because the shingles are small, the surface appears calm and uniform to the eye, despite the variety of colors.

The proportion of scrapcrete and individually made pixels can vary depending on the customer’s wishes. The implementation of a project using 100% residual materials enables maximum resource conservation. The lower the proportion of shingles produced to order, the better the impact on the ecological life cycle assessment.

Installation

pixels are installed in a similar way to a shingle facade made of wood. Each shingle is individually inserted into a clamping rail and fastened with screws or rivets. The overlapping shingles conceal the screw. Other mounting options are available on request. Due to the shingles overlapping, 20% more sqm of pixel is required for a facade area (e.g. facade area of 100 sqm -> 120 sqm pixel).

Everything from a single source - The mounting system with clamping rails that Rieder developed enables simple and quick installation. The delivery content includes the secondary supporting structure (profiles, clamping rails) made from aluminium, screws and pixels. On request, the pixels come pre-drilled, which makes them quicker to install at the construction site.

Our products