New facade aesthetic from leftover materials

Facade specialist Rieder strengthens its main site in Maishofen

To pave the way for a resilient future, Rieder has invested in a sustainable company headquarters in Maishofen. For nearly 20 years, the family business has been internationally successful with the production of glassfibre reinforced concrete facade products.

To expand production capacities, a new hybrid hall combining timber and concrete was constructed. This complements the two existing production halls, sets high standards for the future of building and establishes new benchmarks in prefabrication. Over 1,300 m³ of timber were used in the project. To promote regional value creation, local company Höck Holzbau, based in Maishofen, was brought on board. They manufactured the elements directly on a specially designated area at the construction site, enabling rapid progress.

Modern working environment with natural daylight

180 large timber pyramids were used as ceiling elements. Their special geometry maximises the incidence of light. The use of zenithal light creates a harmonious spatial concept and ensures optimal workplace conditions. In addition, a humidification system was installed. The healthy level of humidity reduces dust exposure and improves air quality for employees. Owner Wolfgang Rieder adds: “The overall architectural concept supports a modern working environment. With the completion of the second timber-hybrid hall, we were able to create numerous new jobs and strengthen the region as a business location.”

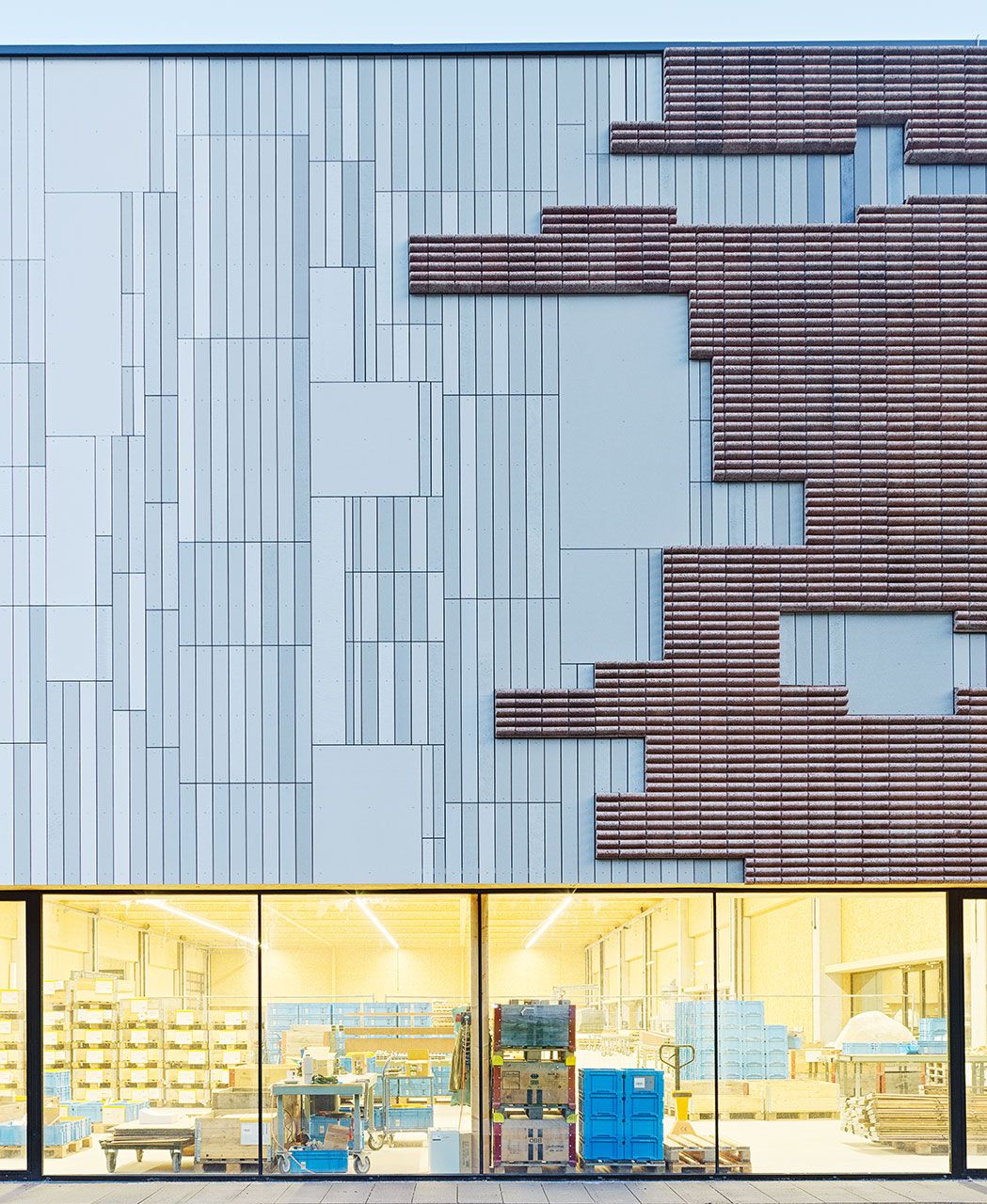

Facade design from leftover materials

Parts of the production halls were clad with discarded absorbers that would otherwise have been disposed of. The front facades of the two halls were covered with production offcuts of glassfibre reinforced concrete. Thanks to comprehensive data analysis of the offcuts, an innovative method of cataloguing and generative algorithm-based design, the architectural design process was reversed: existing material became the basis for a new facade design. Over 500 m² were created from the offcuts and rearranged like a patchwork quilt. In doing so, waste was given a new life, waste volume reduced and resources conserved. By working with the material available and embracing the conditions it presented, a completely new facade aesthetic emerged. This flagship project demonstrates how resource-efficient construction and innovative design can go hand in hand.